|  | Cable / Wire Tension Sensor CableBull®

for measurement on pretensioned cables and belts |  |

| | |  • rugged design, compact lightweight • rugged design, compact lightweight

• comfortable quick lock for threading

• high accuracy and reproducibility

• calibrated for the following material diameters:

1-8 / 4-12 / 8-16 / 14-22 / 20-30 / 24-34 / 30-40 / 36-46mm

• 12 rated load ranges available:

0 to 1kN ... 0 to 300kN |

|

| Description |  |

The sensor is used for tension measurement

• on pretensionend cables and belts in open and closed Force Systems

• at very high forces

CableBull® is the technical innovation

for mobile tension measurement in Closed Force Systems (CFS).

Exact tension measurement in CFS with handheld equipment is up to now not possible and

typically afflicted with high measuring errors.

(Already a small change of the geometry in CFS causes a marked variation of tension.)

The unique conception of Honigmann CableBull® fulfills this complicated measurement job.

CableBull® first-time enables engineers precise measurements in CFS,

with very easy handling:

- take CableBull® to measuring position

- turning the lock-lever 180°

- measuring

|

| Applications |  |

Tension measurement:

• aerial mast stays

• aircraft support cables

• catenary ropes for railways and trams

• guy-wires for antennas and masts

• guy-wires for chimneys

• moving ropes

• overhead cables / open wires

• pre-loaded wire ropes

• ropes for shipping

• ropes for fishing

• small tapes and belts

• suspension and transmission lines

• stay ropes and cables, static wires

• steel wire ropes, braided tension wires

• towing ropes and belts

• solid rods |

Range of application:

• cranes and hoists

• crown bracing on trees

• equalise loadings on multi-cable assemblies

• earthquake-proof construction

• event rope technology

• guying on buildings

• climbing frames

• industry applications

• lifts and elevators

• spreader at container crane

• load spreading of multiple ropes

• manufacturing of pre-stressed concrete PC

• ship rigging / rig

• silo rigging

• ski sites

• hail protection systems

• stage and set building / rigging

• street lighting, christmas illumination

• telescope and extension mast

• staging / scaffolding anchor

• flare stacks / gas flares

• towing of loads

• transportation lock

• vehicle pull and logging

• water ski sites

• cable railing

• steep slope logging

• zip lines

• lifelines

|

|

| Special features |  |

• minimal sensor influence on the tension by smallest deflection angle

(thus avoiding a damage of the rope)

• by means of the Diameter Compensator independent of material diameter

(individual calibration of each material diameter is not necessary)

• hardened steel skids with special DRS-shape of contact surface (Dual Radius Skid)

They are used, when the rope is not moving through the sensor.

• hardened steel rollers with special DRR-shape of running surface (Dual Radius Roller)

They are used, when the rope is moving through the sensor.

• high resolution and precision

CableBull® ... the best world wide

|

| Construction sizes, diameter and force ranges |  |

|

400mm measurement path |

|

Ø range [mm] |

Type |

Nominal force [kN] |

|

|

|

LR (Low Range) |

Standard |

HR (High Range) |

|

1-8 |

S-R08 / 400 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

|

|

|

4-12 |

S-R12 / 400 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

|

|

|

500mm measurement path |

|

Ø range [mm] |

Type |

Nominal force [kN] |

|

|

|

LR (Low Range) |

Standard |

HR (High Range) |

|

1-8 |

S-R08 / 500 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

|

|

|

4-12 |

S-R12 / 500 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

|

|

|

600mm measurement path (Preferred construction size

) |

|

Ø range [mm] |

Type |

Nominal force [kN] |

|

|

|

LR (Low Range) |

Standard |

HR |

XR |

|

1-8 |

S-R08 / 600 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

|

4-12 |

S-R12 / 600 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

|

8-16 |

S-R16 / 600 |

1 |

2 |

3 |

4 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

|

800mm measurement path |

|

Ø range [mm] |

Type |

Nominal force [kN] |

|

|

|

Standard |

HR (High Range) |

XR (Extended Range) |

|

4-12 |

S-R12 / 800 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

200 |

|

|

|

|

8-16 |

S-R16 / 800 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

200 |

|

|

|

|

14-22 |

S-R22 / 800 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

200 |

|

|

|

|

|

|

|

|

|

|

|

|

Standard |

HR (High Range) |

XRX |

|

20-30 |

S-R30 / 800 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

200

|

300

|

|

|

|

24-34 |

S-R34 / 800 |

5 |

10 |

20 |

30 |

40 |

50 |

100 |

200

|

300

|

|

|

|

30-40 |

S-R40 / 800 |

|

|

|

30 |

40 |

50 |

100 |

200 |

300

|

|

|

|

36-46 |

S-R46 / 800 |

|

|

|

30 |

40 |

50 |

100 |

200 |

300

|

|

|

|

1000mm measurement path |

|

Ø range [mm] |

Type |

Nominal force [kN] |

|

|

|

Standard |

HR (High Range) |

XR (Extended Range) |

|

30-40 |

S-R40 / 1000 |

|

|

|

30 |

40 |

50 |

100 |

200 |

|

|

|

|

36-46 |

S-R46 / 1000 |

|

|

|

30 |

40 |

50 |

100 |

200 |

|

|

|

The measuring range of the sensor begins at force’s zero point.

Nominal forces differing from the list are available.

|

| PreView |  |

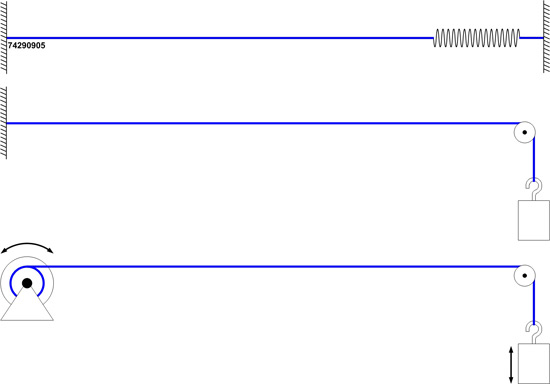

| Schematic diagrams of force systems |  |

CableBull is für suitable for the following applications.

closed force system (CFS):

open force systems:

|

| Animations |  |

Animation |  | Handling

Closing and opening of measuring geometry |

| Variants |  |

InfoZoom |  | Lock-lever on front side

• standard |

|  | |

| Options |  |

InfoZoom |  | CBDT Carrier

• for mounting Digitens® on CableBull®

• stable, rugged design

• for front and rear operation

• with adapted connection cable

|

| Accessories |  |

| Related products |  |

to product page |  | Digitens® 485 DMS

• hand-held

• for strain gauge sensors

• digital display

• auto-zero / hold / peak

|

| Tension measurement on prestressed cables and rods |  |

| The measurement, regulation and control of tensile forces is particularly important for flexible and solid pretensioned materials such as ropes, braces, cables, rods and bars. Only in this way it is possible to permanently provide the necessary functionality and safety. The traction force has to be measured in Closed Force Systems (CFS) and also in open force systems, concerning installation, maintenance and quality assurance. Tension measurement is found in a wide variety of industrial sectors and applications such as rope tension or wire tension of high voltage cables and power lines, winches, suspension cables of elevators and lifts, but also antenna masts, catenaries, festive lighting, street lighting, Christmas illumination, gas torches and flares as well as architectural ropes in the facade construction. In construction engineering, the tension measurement is often used in the bracing of scaffolding and various lashing, but also in the production and testing of prestressed concrete or railway sleepers, as well as the processing of reinforcing bars, concrete iron, reinforcing steel, for tension wires, tension strands and the anchor preload. Tensile force measurement plays an equally important role in industrial applications in cranes and winches, in load distribution in multiple ropes, on the spreader of a container crane or in telescopic masts. In many areas, the measurement of rope tension by means of a cable tensiometer is of particular importance for the safety of the plant, as for the quality assurance of hail protection systems or for silo rigging. In event technology, checking and regulating of the tension forces ensures the necessary reliability, for example in stage technology in the theater, when using winch ropes or in climbing plants and ski sites. The measurement of the cable force allows the correct load distribution and ensures essential functions even with the steep slope harvester, the treetop safeguard or in the airship or captive balloon. Due to the variety and high number of installations, a mobile solution for measuring the tension is usually the only option. However, precisely in Closed Power Systems, it is scarcely possible to measure the tension exactly, or it is typically associated with large, incalculable measuring errors. Even a small change in geometry causes a significant variation in the tensile force. The unique design of the Honigmann CableBull® fulfills this difficult measuring task in a special way. The complex individual calibration, based on the diameter of the material, is not necessary. The Honigmann CableBull® is a purpose-built force sensor and offers easy handling with maximum resolution and accuracy and is suitable for material diameters from 1 to 46 mm and a nominal force of up to 300 kN. The low material deflection ensures minimal influence of the sensor on the tensile force, thus ensuring maximum precision and preventing damage to the material being measured. |

Downloads  | Note:

Viewing of PDF-documents requires Adobe® Reader® - download |

|

|  |  | PRODUCTS |

|  | |

|